AliDeck Supply a Wide Range of Aluminium Balcony Solutions to the Exciting New Build Project at Manor Road Quarter in Canning Town, London, in Partnership with Alloy Fabweld & Morgan Sindall

AliDeck has successfully supplied a diverse range of cutting-edge aluminium balcony solutions to the Manor Road Quarter project in Canning Town, London. The AliDeck Ultra Decking Board, AliRail Plate Fix 0.74kN Option (AliRail System 2), and the aesthetic AliClad Flow Cladding Board will now create a complete balcony solution, as this collaboration with Alloy Fabweld showcases our commitment to innovation and technical excellence.

In a previous article on our website, we announced that Alloy Fabweld had secured the opportunity to work on the Manor Road Quarter project in Canning Town, London, and that AliDeck were entrusted with providing non-combustible balcony solutions. The collaboration was forged through an in-depth meeting with the owner of Alloy Fabweld and the design team before a joint proposal was presented to the team at Morgan Sindall, a leading British Construction & Regeneration group.

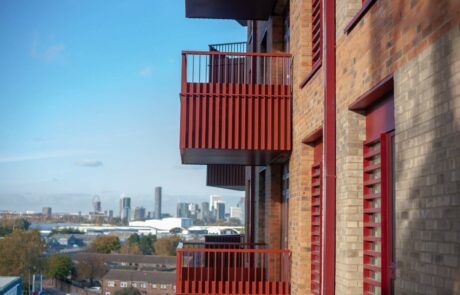

This exciting new-build project will create 855 new homes in total. With AliDeck supplying balcony materials for Phase 2 & 3 of the project. The highest of the three new residential towers will stand 32 storeys high, with the ground floor hosting flexible commercial space along with the multiple apartment types available.

Phase 2 is a 9-storey concrete framed building that will lay home to 61 apartments. Phase 3 stands at 12 storeys high with 79 apartments. Each home will benefit from a balcony that will feature our aluminium decking solutions, providing residents with a safe and futureproof environment for decades to come.

“Through the combined industry knowledge with our partner in balconies, AliDeck, who are experts in non-combustible, quick-fit and easy installation systems, along with our specialist design, engineering and installation within Alloy Fabweld Ltd, we are excited to launch the Triple SSS balcony system.”

– Alloy Fabweld Ltd

Alloy Fabweld, a leader in architectural metalwork for both the Commercial and Residential sectors with over 20 years of experience, has played a pivotal role in the success of the Manor Road Quarter project in Canning Town, London. Their commitment to delivering innovative solutions is evident in the lightweight flat-pack solution, Triple S Balcony, utilised on this project.

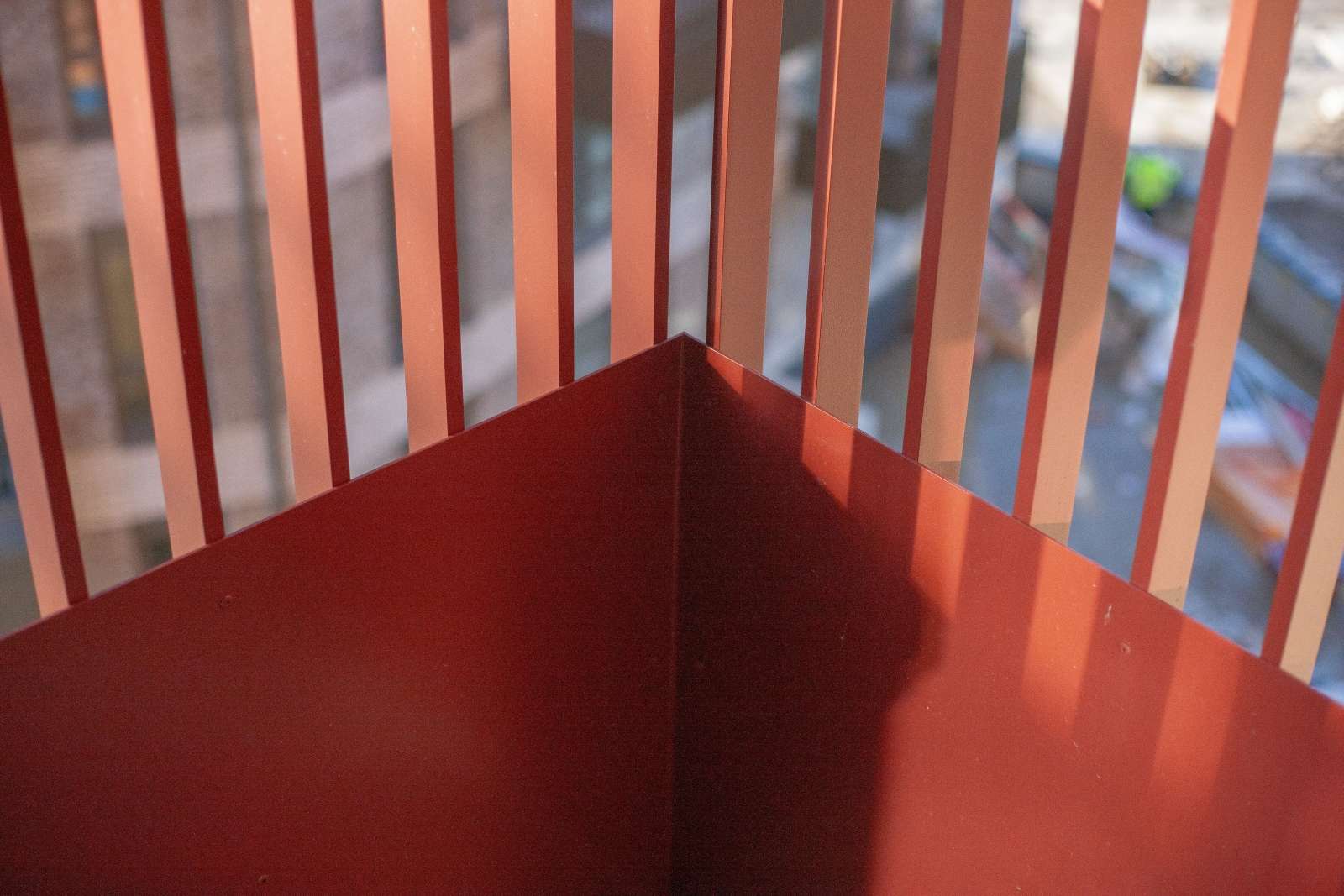

All aluminium decking boards, balustrades, and soffit drainage boards were expertly finished, with Phase 2 utilising our popular RAL 7030 Stone Grey powder-coated finish – one of our 10 standard options. Phase 3 offers distinctive flair, finished in RAL 3009 Oxide Red, a captivating bespoke colours available upon request. All products are powder-coated in-house through our seven-stage pre-treatment facility and highly trained staff using class 2 powders only, well above industry standards.

Innovative Collaboration: Crafting the Triple SSS Balcony – A Pivotal Design Element in Securing Project Success

The use of Triple SSS Balconies played a pivotal role in the success of the Manor Road Quarter project. Weighing only 850kg based on this balcony size, these lightweight flat pack solutions drastically reduce weight while meeting stringent deflection criteria.

Beyond its weight advantages, the Triple SSS Balcony significantly enhances project efficiency. Its flat pack nature reduces installation time and material costs, underscoring its impact on both the project timeline and budget. This innovation combines versatility with adaptability, offering architects and builders the freedom to create unique balcony configurations efficiently on-site.

The Triple SSS Balcony symbolises more than a construction element; it represents the forward-thinking ethos of AliDeck and Alloy Fabweld. In the context of Manor Road Quarter, this solution sets a new standard for lightweight, efficient, and structurally sound balcony design, showcasing the power of collaboration in pushing the boundaries of traditional construction practices.

Comprehensive Excellence: Leveraging the Power of Multiple AliDeck Brands for Holistic Balcony Solutions

The installation of AliDeck’s Ultra Balcony Board with built-in Drainage Channel for effective water management expertly fitted to create a secure and visually appealing decking solution. The 60mm concealed fixings channel is ideal for placement of lifting eyes to allow for craning completed balconies into place with all boards pre-installed. Fast and hassle-free installation is guaranteed with the invisible top clip system which can be installed from the top down.

Our Plate Fix 0.74kN Option, also known as AliRail System 2, reinforces our commitment to safety and functionality. Collaborating with Alloy Fabweld for the external Fascia Plates, the 0.74kN Plate Fix option ensures a secure and visually pleasing balustrade system. The AliRail brand highlights our dedication to top-tier balustrade solutions that complement the overall design of the balconies.

The AliClad Flow Cladding Board adds a distinctive touch to the project. Carefully customised to a length of 5240mm, these boards are expertly fitted to enhance the aesthetics of the balconies. The Flow Board ensures effective drainage at soffit-level to channel rainwater and spillages away from balconies and pedestrian walkways below, while maintaining a high-quality finish that elevates the visual appeal of the project’s exterior.

Unveiling the Many Advantages of utilising AliDeck’s complaint and futureproof Aluminium Balcony Solutions

The efficiency of custom extrusion not only streamlines the ordering process but also eliminates the need for on-site cutting, saving valuable installation time. At AliDeck, we recognise the importance of delivering not only high-quality products but also cost-effective solutions. Choosing custom extrusion empowers our customers to tailor their orders precisely to project specifications, resulting in substantial cost-savings that can make a remarkable difference in the overall project budget.

Incorporating aluminium into the Manor Road Quarter project not only ensures durability but also leverages the material’s unparalleled strength-to-weight ratio. Pound for pound, aluminium is the strongest metal, offering structural integrity without compromising on weight. This characteristic is pivotal in creating robust structures while maintaining overall project efficiency.

All of our products boast excellent fire-ratings of A2-s1, d0, and A2fl-s1 standards, in accordance with BS 8579:2020. Achieving among the highest EuroClass ratings, these products underscore AliDeck’s dedication to safety and compliance.

AliDeck’s Ultra Decking Board meets the required Slip Resistance required following extensive testing, as the flat surface design scored well above the industry standard. All drainage solutions specified were approved by NHBC Standards Team, as this project utilises both deck-level and soffit-level drainage methods.

From innovative lightweight balconies to bespoke extrusions and fire-rated products, AliDeck’s contribution to this project showcases its position as a trail-blazing innovator within the industry. By seamlessly integrating multiple AliDeck brands, prioritising safety, compliance, and harnessing the unique benefits of aluminium, we have played a pivotal role in creating a fire-safe and futureproof environment for the Manor Road Quarter development.

Would you like more information about this exciting new-build project in Canning Town, London?

If you would like to discuss further how we can best support and help you achieve compliant and fire-safe balconies for an upcoming new-build project, We’d love to talk to you. Simply contact us via 01622 235 672 or email info@alideck.co.uk.