AliDeck Approved Installer delivers Major Fire Safety Remediation Project to Balcony and Terraces at large housing association development in Southwark, close collaboration key to success

Fire safety remediation in the external envelope continues to be a key issue affecting the housing sector. As industry adapts to new regulatory realities post-Grenfell, the need to bring existing multi-occupancy housing stock into compliance remains urgently pressing. Each building or development that is successfully remediated, though, represents one further step towards our fire safe future.

We are very pleased, then, to share the excellent progress that has been made on a major remediation project using AliDeck in Southwark for Wandle Housing Association.

Comprising several four-storey blocks at Evan Cook Close, fire safety issues were identified in the external envelope of the buildings as part of EWS1 inspections. Specifically, the timber decking present in large quantities across the balconies, roof terraces and common walkways posed a major risk, preventing a compliant EWS1 certificate being issued.

The EWS1 crisis has caused untold pain for all stakeholders since very shortly after its launch in December 2019. The Government issued the Consolidated Advice Note just one month later which required multi-occupancy buildings of all heights to be considered for fire-safety requirements, derailing EWS1 immediately with the huge influx of additional buildings into scope and trapping homeowners in unmortgageable properties.

Delivering the right solution

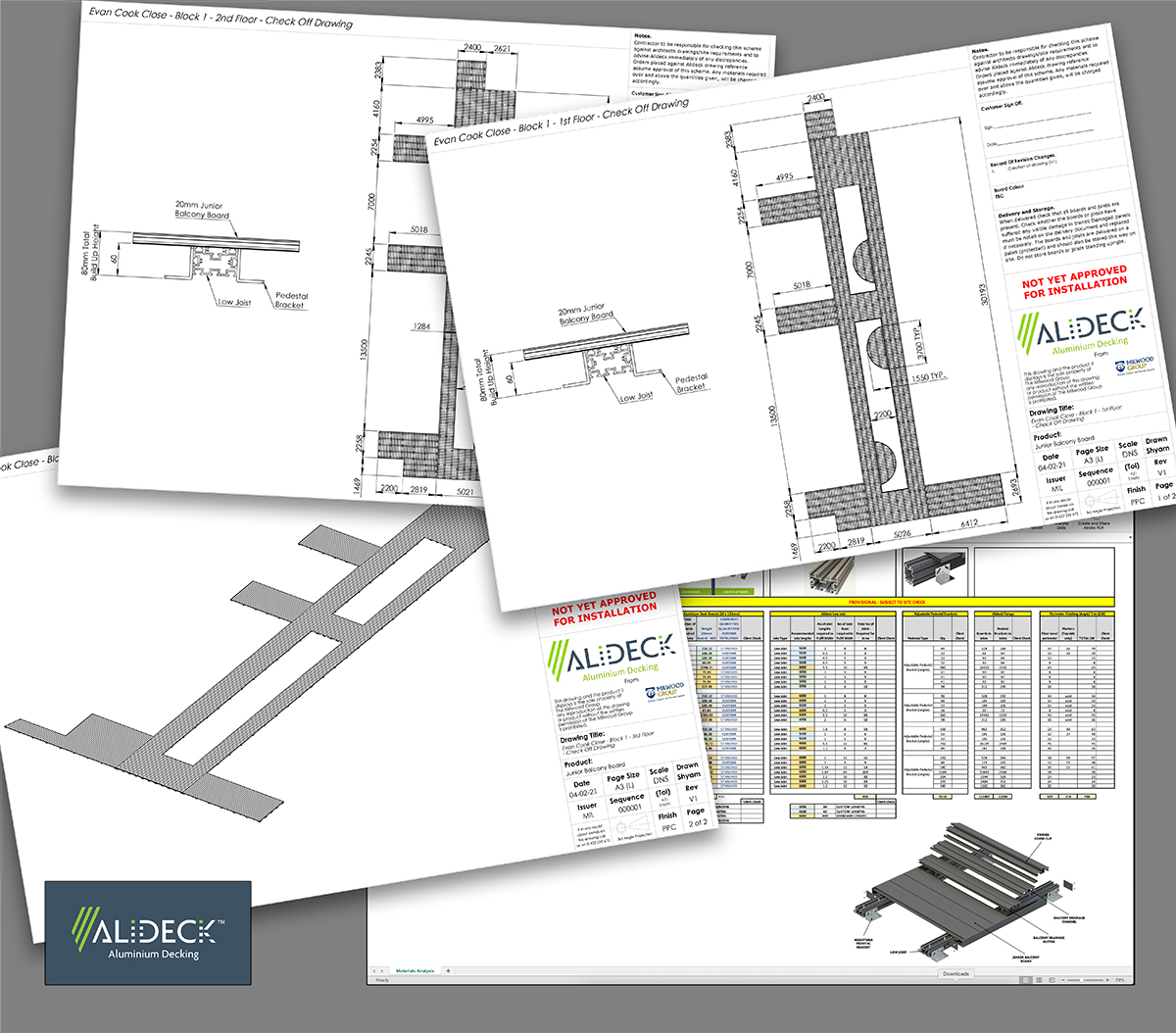

The Wandle buildings at Evan Cook Close were unfortunately caught up in EWS1 so the essential remediation works began to be planned to solve the issue. Construction and roofing specialists Breyer Group were appointed as main contractor for the refurbishment and AliDeck became involved with the project in early 2021, with our team conducting extensive site surveys to begin to understand the materials requirement to replace the dilapidated, combustible timber decking.

Part of AliDeck’s commitment to our customers is that we will collaborate closely from the earliest stages to ensure that the right specification is made for each project. This includes both identifying the right product solutions and correct materials quantities, to guarantee maximum cost-effectiveness and to enable the success of the project in all aspects.

Our approach for Evan Cook Close was led by this philosophy, with the AliDeck team on site at the earliest opportunity to inspect all areas and ascertain the physical requirements. Our investigation revealed a complex proposition with multiple falls to waterproofing layers, curved raised flowerbeds, branching decked walkways, and more.

Compounding these difficulties was the lack of detailed architectural drawings for the buildings, requiring us to essentially conduct our survey blind and invest significant effort in learning the nature of the building hidden beneath the in-situ existing decking.

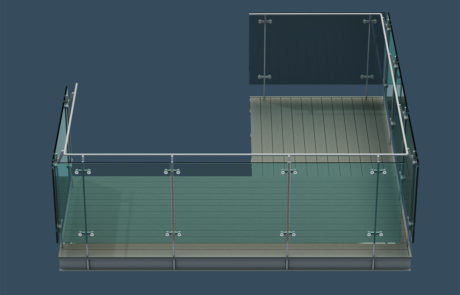

Fortunately, the AliDeck team and the project contractors were able to combine their expertise to create a detailed overview of the project requirements. These findings then informed our proposal stage where we composed the most suitable solution for each distinct area of the decking remediation works, building a detailed matrix of suitable products comprising aluminium decking boards, joists, pedestals, fixings and more, and providing concept artwork to provide an understanding of the aesthetic impact of the product proposal.

Collaboration from inception to completion

The decking replacement works were to be completed by Alu-Installations, an AliDeck Approved Installer. George and his team at Alu-Installations are experts at working with our products, being one of the earliest teams to complete our Training Academy process in 2019. Having now completed many similar remediation and install projects, a real depth of understanding was immediately available to the project from George and his team.

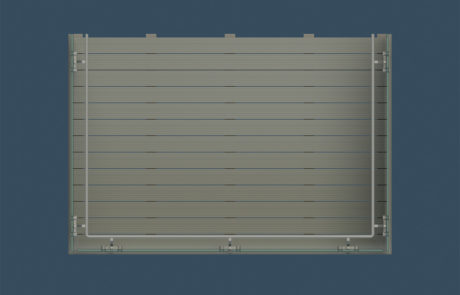

Working with George to create our full proposal, our 20mm Junior Decking Board was ultimately chosen by Wandle and Breyer Group. Paired with our Low Joist and Adjustable Pedestal Brackets, the versatility of the non-combustible Junior Board System proved key for application across the whole site.

Using the data gathered from our site visits, we were able to create an accurate bill of quantities and provide Wandle, Breyer Group, and Alu-Installations with a detailed breakdown of items required for each area, allowing for scheduling and call-offs to be easily arranged.

Visiting the almost complete project recently, it was deeply rewarding to see the excellent outcome achieved. In particular, the large roof terrace is strikingly impressive, with the aesthetic impact of the new decking completely transforming the space.

A key feature to this roof terrace area is the large, raised flowerbeds. With a curved, semi-circular frontage they posed a real challenge in terms of finishing. While it was a simple decision to use the Junior Board vertically to directly replace the existing timber decking on these frontages, leaving the aluminium cut edges exposed was an unacceptable injury risk.

Alu-Installations proposed and designed a bespoke trim solution to overcome this challenge. Colour-matched right-angle trims were rolled to achieve the curvature and provided a safe, seamless finish to the feature flowerbeds.

The roof terrace was installed above a waterproof membrane and this protective layer had multiple falls for drainage, leading to varying build-up height. Our Adjustable Pedestals were carefully specified to provide the correct range of adjustment to the whole area to achieve a level pedestrian surface.

Work was required to pause briefly at this stage due to defects being found in the waterproofing when the timber deck was removed. Whilst this break in proceedings was unfortunate, it ultimately proved no major impediment as our operations-focused approach to the supply of the project was suitably robust to cope with such hiccups.

With the waterproof layer suitably renewed, installation of the new aluminium decking system was able to proceed across all roof terrace areas before moving to the balconies and common walkways.

For the balconies, the timber decking replacement was a simple matter of like-for-like replacement. The aluminium decking system of boards and joists directly fixed to the existing balcony steel framework, immediately rendering the balconies fire safe. The addition of our Balcony Drainage Channel between the boards provided a controlled water management solution, improving upon the prior free-draining arrangement on the balconies.

An additional aspect that required remediation on some balconies was privacy screens. Constructed from timber fixed to a steel frame, our non-combustible AliClad Lite cladding board was chosen to supply a simple, cost-effective, and highly practical replacement solution.

The AliClad range is designed as balcony soffit cladding use but as a simple extruded aluminium board, though, there is no reason why it can’t be used in a vertical position. This versatility is being increasingly recognised across industry, with several major projects currently looking to adopt this AliClad Lite privacy screen solution.

The progress made on this project is very encouraging to see and the finishing line is in sight. The AliDeck team has been deeply involved with this project for 12 months now and we are proud to see our effort pay off in the successful remediation of these buildings. The close collaboration at all stages between ourselves, Wandle, Breyer Group, and Alu-Installations has delivered an excellent outcome for the project, has helped ensure another building is fire safe for its residents, and provides a template for others to emulate to genuinely solve the building safety crisis.

To find out how AliDeck can help you specify compliant materials for your essential fire safety remediation works or how one of our Approved Installers such as Alu-Installations can work with you to complete these complex works, call us now on 01622 235 672 or email info@alideck.co.uk.