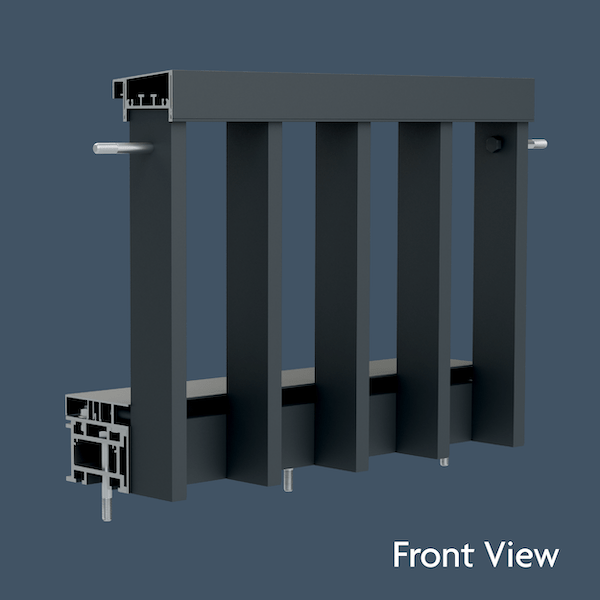

Inner-Mounted Option Specification

- Fire resistant: A2-s1, d0

- Coating thickness – 60-80 microns

- Coating Impact test – with an energy of 2.5Km to ensure that the coating adheres to the substrate to EN ISO 6272 / ASTM D2794

- Bend test – on 5mm mandrel to ensure adhesion after bending to EN ISO 1519

- Machu Test (accelerated corrosion test) in a solution made up of sodium chloride cetic acid and hydrogen peroxide at 37 degrees C Duration 48 hours

- Qualicoat 2.4.1. – cross hatch cuts are made at 2mm spacings with one being at 90 degrees to the other cut, tape is the applied left for 2 minutes and removed to check for adhesion of paint (EN ISO 2409 2013)

- Qualicoat 2.18 – sawing and drilling test to ensure no flaking after cutting (using sharp tools)

- Acid salt spray test – ISO 9227

- EN ISO 3231 – Resistance to humid atmospheres containing Sulphur Dioxide

- EN ISO 11341 – Accelerated weathering test

- EN ISO 20810 – Natural weathering test (Florida Test) (Carried out on Powder Type)

- EN ISO 12206-1 – Resistance to mortar (Carried out on powder type)

- EN ISO 6270 – 2 – Constant climate condensation water test

- Choice of colours – Available in a wide range of RAL colours

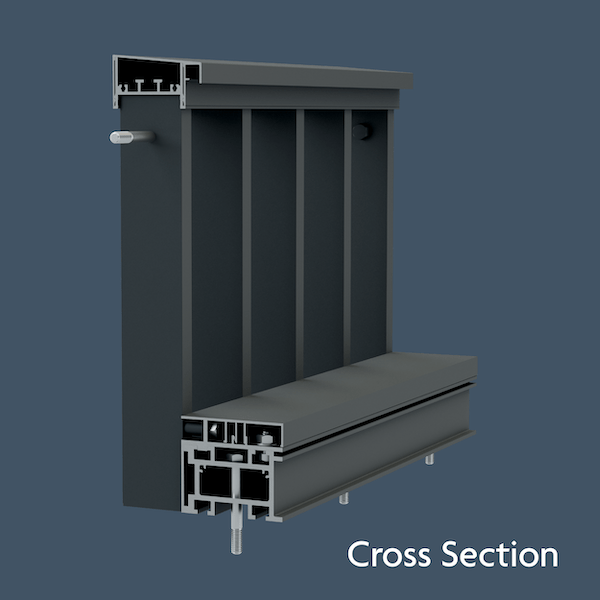

- Contemporary aluminium metal balustrade system.