In-House Manufacturing: The Secret to Consistent Compliance and Fast Lead Times

In a demanding construction industry, reliable lead times and guaranteed compliance are critical. One major factor influencing both is whether balcony systems are manufactured in-house or outsourced overseas.

The Power of In-House Manufacturing

At AliDeck, we manufacture and powder-coat our aluminium balcony solutions in house. This enables us to maintain strict quality and compliance controls, achieve consistent high-standard manufacturing, and offer rapid responses to specification changes.

Immediate quality inspections during manufacturing, faster resolution of technical or compliance queries, greater supply chain stability, and a reduced environmental footprint through minimised transport emissions are just some of the benefits. In-house manufacturing is the cornerstone of quality assurance, giving clients complete confidence in their balcony systems.

Achieving Quick and Reliable Lead Times

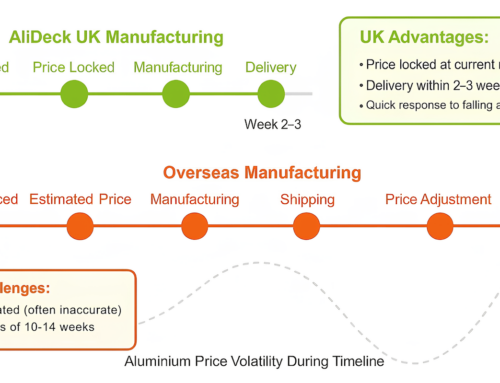

Long overseas supply chains often cause unpredictable delays, risking project completion dates. AliDeck’s in-house manufacturing model enables us to offer lead times of as little as four weeks — significantly faster than the industry standard of six to twelve weeks.

Producing in-house also means full traceability on materials, processes, and testing. We ensure every product delivered meets the latest BSR requirements and industry standards, giving peace of mind to developers, contractors, and housing associations.

Why Choosing AliDeck Makes a Difference

Faster lead times keep construction schedules on track, reduce project holding costs, and improve cash flow by enabling quicker handovers. Our proven ability to meet tight deadlines has made us a trusted partner for some of the UK’s largest developers and contractors.

By choosing AliDeck, you benefit from British-made products that combine innovation, durability, and full regulatory compliance.

Let’s support your next project together. Contact us at info@alideck.co.uk or call 01622 534050.