Innovation for customer and compliance needs

In today’s-built environment, the need for forward-thinking balcony systems is more important than ever. At AliDeck, innovation is embedded in our culture, allowing us to respond quickly to regulatory changes and better support the architects, developers, contractors, and housing associations we serve across the UK and Ireland.

Meeting the Challenge of Modern Compliance

As legislation continues to evolve, particularly under the Building Safety Act and post-Grenfell regulations, developers are under pressure to specify products that not only meet compliance but also stand up to scrutiny. Our aluminium balcony systems are manufactured to meet the strictest standards — including full compliance with A2-s1, d0 and A2fl-s1 fire ratings — ensuring safer outcomes for both residents and stakeholders.

We understand that non-compliant materials can delay projects, incur penalties, and compromise safety. That’s why every product we release is designed with compliance at the core, offering confidence for new builds and remediation alike.

Designed for Performance and Durability

Innovation at AliDeck also means continuously improving performance. We’ve developed a full suite of systems — including decking boards, soffits, balustrades, and privacy screens — that not only exceed safety standards but are also engineered for strength, weather resistance, and long-term durability.

Recent product enhancements include our new Slimline Handrail, which delivers a contemporary aesthetic without compromising on load-bearing requirements. Additionally, our AliClad Flow soffit system integrates drainage functionality directly into the soffit, improving water management on balconies while reducing install time.

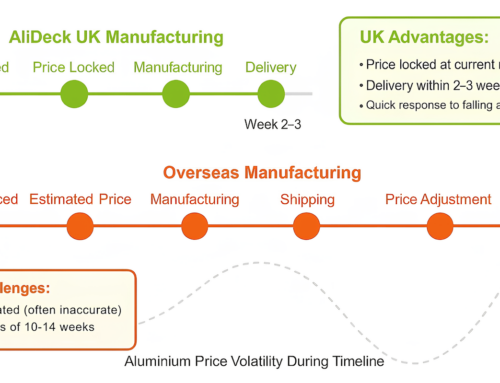

Fast Lead Times and UK Production

One of our key advantages lies in our UK-based supply chain. While many competitors rely on overseas suppliers and face extended lead times, AliDeck extrudes aluminium in the UK and completes all manufacturing and powder coating in-house. This allows us to maintain lead times of just four weeks — significantly quicker than the industry average of 6–12 weeks — and gives our customers greater control over their project timelines.

Being Made in Britain certified is not just a badge for us — it’s a promise of quality, accountability, and consistency. It also enables faster resolution of any issues, should they arise, due to our complete local oversight.

Evolving with Our Customers

We believe innovation should always be user-led. By engaging with our customers — from site visits with steel fabricators to CPD sessions with architects — we gather the insights that drive change. Whether it’s simplifying installation methods, developing lighter components, or introducing digital tools to aid in specification, we adapt quickly to what our partners need most.

To further support this, we are constantly expanding our design and specification resources, including BIM-ready files, CAD drawings, and spec sheets, ensuring that professionals can integrate our systems easily and accurately.

Looking for a future proof partner? Let’s work together to elevate your next project.

📩 info@alideck.co.uk | 📞 01622 534050