Further testing on heat performance of aluminium decking versus timber and composite decking, core material temperature measurements reveal compelling data

The warm weather across the UK is continuing with bright sunshine and high temperatures a daily occurrence now for several weeks. Taking advantage of the fine weather, we decided to take another look at the question of whether aluminium decking becomes too hot.

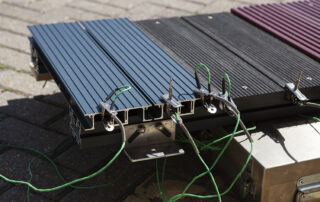

Further to the recent reflective surface temperature testing we conducted on aluminium, composite, and timber decking, we have now performed material core temperature testing using some sophisticated equipment from our powder-coating line!

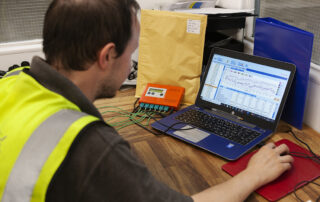

The Elcometer 215 Oven Data Logger is a temperature profiling device used to continuously record material temperature as it passes through our powder-coat oven. It is essential for the powder-coat curing process for the material being coated to reach certain temperatures so the use of this device, alongside other lab testing, helps us be sure that our products have been correctly powder-coated.

Able to measure up to six different temperatures at one time, the Elcometer Oven Data Logger is a versatile and robust tool. Its probes are held in close contact to the material surface by crocodile clips and accurately record the actual material temperature at user-defined intervals.

Utilising our heat test rig again, we connected probes to all three types of decking board and also set two probes up to measure the ambient air temperature. Taking readings every 5 seconds across one hour while the test rig is exposed to sunlight, the data captured paints a revealing picture.

| Material | Maximum Temperature after 1 Hour in Sunlight |

|---|---|

| Aluminium | 40.9°C |

| Composite | 39.3 °C |

| Timber | 37.0 °C |

Note: Ambient air temperature: 25 °C. Test conducted between 11am and noon, 4th August 2022 in Rochester, Kent

So, the material core temperatures of aluminium and composite decking after one hour in the sun were almost the same, and timber decking was only a few degrees cooler! Due to its excellent thermal conductivity, the aluminium decking also dissipated its heat quickly once shaded, while the composite decking especially remained hot.

Looking at our earlier reflective surface temperature testing we performed, we saw an almost 10°C cooler average temperature on aluminium (46.65°C) compared to composite (55.95°C) and timber (54.15°C) decking in that testing.

With these two datasets, we can now form an objective opinion as to the heat performance of aluminium decking versus the traditional timber and composite decking solutions; aluminium decking does not get significantly hotter than the other materials, neither in its material core or at the surface.

Indeed, its thermal conductivity properties allow it to quickly shed any heat gained so while it might feel hot-to-the-touch in direct sunlight, as would composite or timber decking to around the same level, the aluminium decking would become cool again much more quickly!

Whatever the material, if your balcony or terrace decking is exposed to bright, direct sunlight in the middle of summer it is likely to become uncomfortably warm. Categorically now, though, we can say that aluminium decking does not have a specific problem with becoming too hot.